Steel Coking

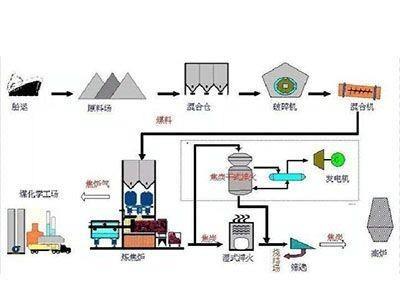

The entire smelting process of the iron and steel industry from coking, sintering, ironmaking, steelmaking to steel rolling involves different types of pollutants, covering three types of waste gas, waste water and slag.Specifically, the sintering and cok

Consult now

Specifically, the sintering and coking processes mainly produce exhaust gas such as sulfides, nitrogen oxides and soot, the iron and steelmaking processes mainly produce solid wastes such as slag, and the pollutants generated in the steel rolling process are mainly wastewater pollution such as cooling water. Among them, gaseous pollutants such as sulfides, nitrogen oxides and soot generated in the sintering and coking process are the most serious.

The exhaust gas produced by the iron and steel industry is dominated by sulfides, nitrogen oxides and soot, mainly from the pre-iron links such as coking, sintering, and pelletizing. Take the exhaust gas pollutant emissions of a large-scale steel company (9.7 million tons) with a long process as an example. The smoke/dust emitted by the company mainly comes from the raw material system (accounting for 19.5%) and the ironmaking system (coking + sintering + pellets + Ironmaking, accounting for 62.3%) and steelmaking systems (accounting for 13.5%), the three together account for 95.3% of the total smoke/dust emissions from the steel industry. Specifically, SO2 mainly comes from pellets (accounting for 34.1%), sintering (accounting for 25.1%) and captive power stations (accounting for 27.5%), accounting for about 86.7% of the total emissions; NOX mainly comes from sintering (accounting for 30.9%), Captive power stations (23%), pellets (15.1%), and coking (9.9%) account for about 78.9% of total emissions.

our client

Quality creates value, forge ahead, keep moving forward

Our equipment

Tailor-made to provide competitive solutions and services, driven by details to determine quality

Ton bag packaging machine

1. Structural principleThe ton bag packaging machine adopts feeding structure such as star unloader, spiral, curved door, vibrating feeder, etc. The control method is stepless frequency conversion speed control or multi-stroke cylinder control, combined w

Palletizing conveyor

Product introduction The unique linear actuator of the palletizing conveyor, the energy-saving and environmentally friendly arm design, the simple operation interface and the customized gripper, can customize professional robot solutions for different p

Pallet conveyor

In the in-and-out system of an automated warehouse, the functions of an automated pallet conveying system generally include conveying, receiving, processing and storing materials, and usually include the completion of size inspection, weighing and automat

Open pouch packaging machine

1. Structure principleThe open pouch packaging machine adopts a gravity feeding structure. The feeding speed is divided into three speeds: large, medium and small, to ensure the speed and accuracy of weighing. It has the characteristics of simple structur

High-position palletizer

High-position palletizer is a kind of high-efficiency high-position palletizing equipment with high degree of automation and good integration. The palletizer arranges the packaging bags according to the requirements and then uses the manipulator to neatly

Contribute a world powder equipment brand to China

Tailor-made to provide competitive solutions and services, driven by details to determine quality

Customization process

Contribute a world powder equipment brand to China

01Communication

02Program

03Confirm

04Order

05Quality

06Logistics