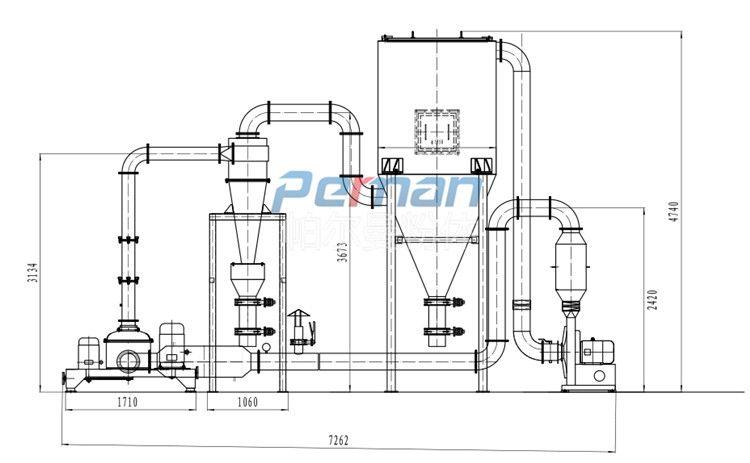

CAM-S Double Shaft Mechanical Crusher

Product introduction: During the operation of the double-shaft mechanical crusher, the materials are evenly sent to the crushing chamber by the feeding system and are strongly impacted by the high-speed rotating crushing disc. At the same time, they ar

Product introduction:

During the operation of the double-shaft mechanical crusher, the materials are evenly sent to the crushing chamber by the feeding system and are strongly impacted by the high-speed rotating crushing disc. At the same time, they are subjected to centrifugal force and collide with the crushing ring gear, and are subjected to shear, friction, collisions, etc. The effect of this kind of comprehensive force makes the material crushed. The crushed material moves to the classification area with the airflow. The coarse and fine materials are separated through the grading wheel adjusted by frequency conversion. The products that meet the fineness requirements enter the cyclone collector and the dust collector to collect with the airflow. , The coarse materials are returned to the classification area for secondary crushing.Features:

1. In line with the new version, in line with GMP, C-GMP, FDA certification requirements2. It can be manufactured according to ISO, DIN, IDF, SMS, 3A, JIS standards

3. Contains grading device, flexible granularity adjustment, reasonable structure and accurate grading

4. The sealing system processed by CNC machine tools (HARDINGE, USA) ensures the design performance

5. Humanized design, easy to disassemble and clean, without any dead corners

6. Design of low-temperature cryogenic crushing process for heat-sensitive materials

7. Flammable, explosive, and oxidizing materials can be used for inert gas closed-circuit protection and crushing

8. Siemens PLC automatic control system, simple and convenient operation

Product advantages:

Integrated design of crushing and grading, the ideal product size can be obtained by adjusting the grading wheelCompact structure, small footprint, low installed power, wide application range, and high cost performance

According to the characteristics of the material, the crushing parts can be flexibly changed (rod, hammer, tooth, etc.) to obtain different crushing forces to improve crushing efficiency

Suitable for product crushing between D50 5~75um

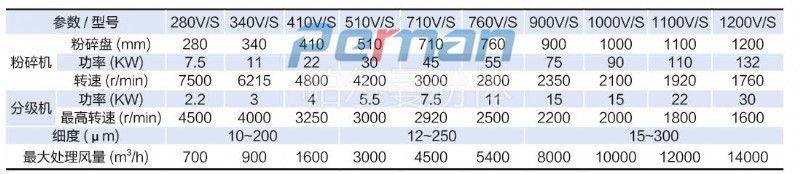

technical parameter:

Related Products

Related cases

Online customization

Quality creates value