CAM-VZ Positive Pressure Air Grinding Machine

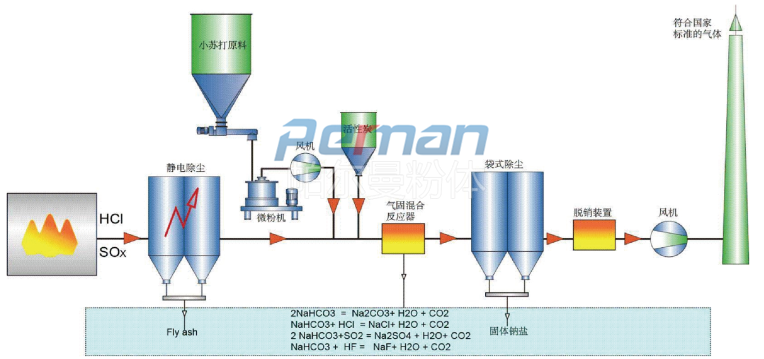

The flue gas contains a lot of acidic gas. After a lot of data and experiments, only sodium bicarbonate (baking soda, NaHCO3) can react with the acidic components in the flue gas to a certain degree. It removes acidic pollutants in the flue gas through chemical adsorption, and it can also remove some inorganic and organic trace substances through physical adsorption. This process sprays fine sodium bicarbonate powder directly into the high-temperature flue gas. At high temperatures, sodium bicarbonate decomposes to produce sodium carbonate Na2CO3, H2O and CO2.

Generally, the flue gas temperature is between 140 and 250 °C. Due to the high activity of the sodium bicarbonate adsorbent, a slight excess of sodium bicarbonate (stoichiometric factor between 1.1 and 1.3) is usually sufficient.

CAM-VZ Positive Pressure Air Grinding Machine

The problem of equipment fouling in negative pressure air grinding systems is often the focus of discussion. The cleaning of the equipment, especially the cleaning of the conveying fan, is too time-consuming. In addition, the fouling on the fan impeller may also peel off during the startup and shutdown process, resulting in the vibration of the fan and the oscillation of its operating state. Therefore, it can be considered to change from a negative pressure process to a positive pressure process. In the new working mode, the fan is installed before the classifying mill, and the process air is forced into the grinding system. The advantage of this working mode is that the ground sodium bicarbonate is not transported through the fan, which completely avoids the problem of fan fouling. In addition, the power consumption of the fan has also been reduced, resulting in lower operating costs, but a higher test is put forward for the sealing performance of the equipment. The design structure, processing accuracy and coordination of the equipment have strict requirements, and the cost of the equipment is also Will be higher.

The dry adsorption process has made a breakthrough in the removal of gaseous inorganic pollutants. This process has become one of the standard processes for removing hydrogen chloride, hydrogen fluoride and sulfur oxides, and is especially suitable for on-line purification of flue gas in incineration plants.

Through the new development of process and equipment technology, the performance of the dry flue gas purification process can be compared with the more efficient wet process. The applicability and economy of the dry flue gas purification process using sodium bicarbonate requires a separate analysis for each case.

The use of Perlman CAM-based sodium bicarbonate grinding system will make an important contribution to this achievement. The flexible customization of the grinding system and the simple and durable equipment effectively improve the availability of the process and the reliability of the flue gas purification process.

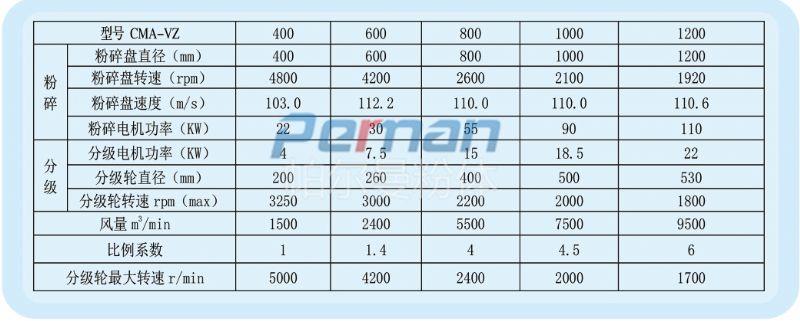

technical parameter:

Related Products

Related cases

Online customization

Quality creates value