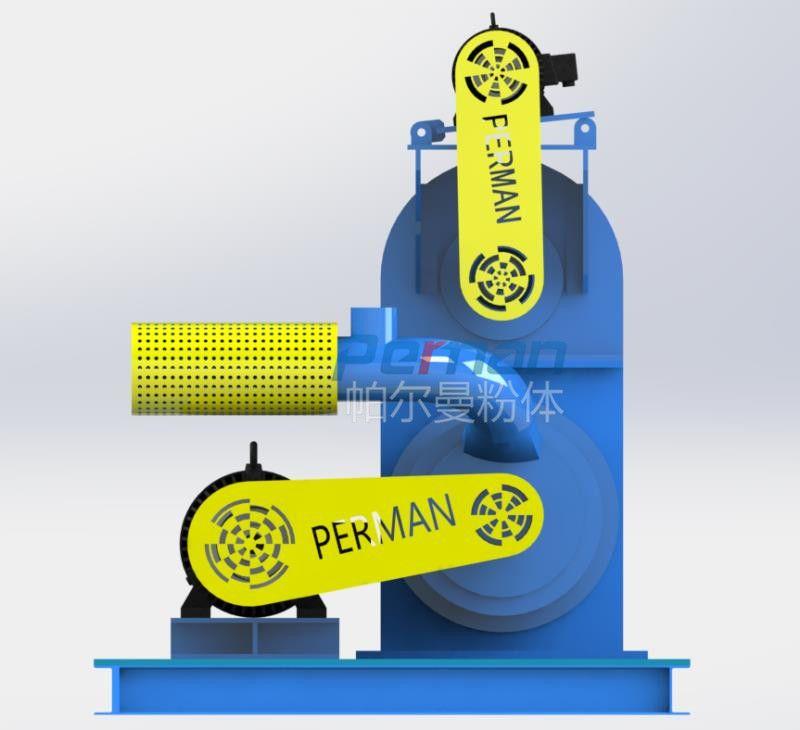

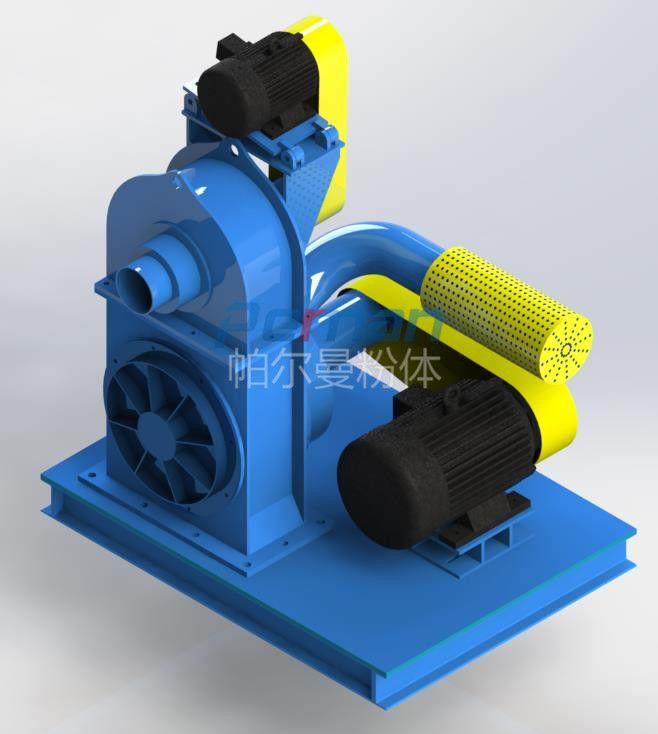

CAM-Y Mechanical Grinding Machine

The two-stage impact ultra-micro grinder includes a first-stage grinder. The upper part of the grinder is equipped with a grinding channel, and the upper part of the grinding channel is equipped with a classifier, which is connected by a flange. The classifier is equipped with a fan for sucking the ground material into the classifier. , The lower part of the classifier is provided with a classification channel communicating with the grinding channel. For the secondary grinder, a liner is added at the lower part, a crushing disc is added inside, and an independent door can be set up on one side for easy inspection. Place the secondary grinder under the classifier, the material after the first level grinding enters the secondary grinder along with the airflow and is impacted by the secondary grinding hammer, and the material after the two impacts enters the classifier for sorting, and the fineness is qualified. The material passing through the classification wheel enters the collection system, and the unqualified materials return to the secondary grinding zone for re-grinding. In order to prevent the temperature of the cavity from rising after the secondary grinding, water circulation can be increased on the outer wall of the cavity without damaging the properties of the material. After adding the secondary grinder, for different materials, the capacity and fineness are increased by 30-60% compared with the traditional grinder, thus greatly reducing the energy consumption. Such repetition makes the material crush more finely, and at the same time, there is no problem of material storage, and the utilization rate of the material is improved.

Product advantages

The two-stage impact ultra-micro grinding machine is a new type of ultra-micro grinding machine newly developed by Weifang Perlman Powder Equipment Co., Ltd. on the basis of the traditional grinding machine. The grinding block collides with the ring gear. After grinding, it enters the classification zone with the airflow. Some materials cannot be returned to the grinding zone for secondary grinding, and some materials cannot be returned to the grinding zone due to the limited primary grinding force, so finer particle size cannot be obtained. , And some have to carry out regular slag discharge due to the inability to grind. After the traditional mill smashes and classifies the material, the coarse material can no longer be returned to the grinding system for secondary grinding. Even if it can return to the grinding zone, the grinding force in the grinding zone is weak, so finer particle size requirements cannot be obtained. We can only consider wet grinding or jet mill grinding, which has high energy consumption, extremely low grinding efficiency, and greatly increases production costs. The two-stage impact ultra-micro grinder developed by our company, after adding the second-stage grinder, for different materials, it can increase the capacity and fineness by 30-60% compared with the traditional grinder, thereby greatly reducing the energy consumption. Such repetition makes the material crush more finely, and at the same time, there is no problem of material storage, and the utilization rate of the material is improved.

Related Products

Related cases

Online customization

Quality creates value