CAM-Y solid waste baking soda crushing system

Hazardous waste treatment, steel plant coke oven, thermal power generation, municipal waste, sludge incineration, non-metallic ore burning, ceramic industry, glass manufacturing

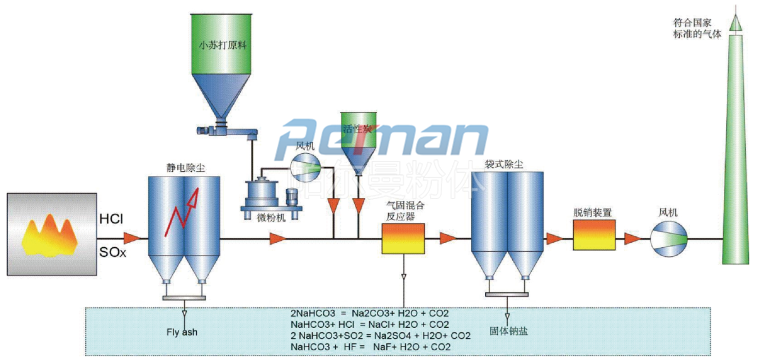

With the increasingly stringent requirements of environmental protection laws and regulations, Perlman's process based on the principle of dry deacidification of baking soda developed in combination with advanced processes in Europe and the United States has been applied more and more. The dry method using sodium bicarbonate as the adsorbent adsorbs and removes various pollutants contained in the flue gas. Its purification effect can be compared with other known methods, such as the spray adsorption method using lime milk as the adsorbent. Dry flue gas purification can be used not only in coal power plants, hazardous waste treatment, municipal waste or alternative fuel incineration plants, but also in industrial furnaces in glass, cement, metallurgy and other industries. Dry flue gas purification can economically remove gases containing acidic substances, such as SO2, HCI, etc., and meet the national standard for flue gas emission.

The flue gas contains a lot of acidic gas. After a lot of data and experiments, only sodium bicarbonate (baking soda, NaHCO3) can react with the acidic components in the flue gas to a certain degree. It removes acidic pollutants in the flue gas through chemical adsorption, and it can also remove some inorganic and organic trace substances through physical adsorption. This process sprays fine sodium bicarbonate powder directly into the high-temperature flue gas. At high temperatures, sodium bicarbonate decomposes to produce sodium carbonate Na2CO3, H2O and CO2.

Generally, the flue gas temperature is between 140 and 250 °C. Due to the high activity of the sodium bicarbonate adsorbent, a slight excess of sodium bicarbonate (stoichiometric factor between 1.1 and 1.3) is usually sufficient.

The particle requirements are related to the components in the flue gas, and the required particle size for the removal of SO2 and HCl will be different. Due to transportation and storage reasons, sodium bicarbonate raw materials are usually coarse particles (d50 value of about 200 microns). To achieve higher reactivity, the adsorbent must have a larger specific surface area. Therefore, the sodium bicarbonate must be ground to a certain degree of fineness before being injected into the flue gas pipe. For example, the fineness of sodium bicarbonate must reach d90 <20 µm to remove SO2. The removal of HCl only requires d90 <35 µm. If the system is operated correctly, it can remove more than 95% of SO2; the removal rate of HCl can even reach 99%. In order to maintain the required fineness of sodium bicarbonate during long-term operation, after grinding with an air grinder, the adsorbent is transported by gas transportation and directly passed into the flue gas pipe through multiple nozzles to ensure that it is evenly dispersed in the pipe. . The design of this equipment is simple and durable. Compared with other flue gas purification methods, its investment and operating costs are lower.

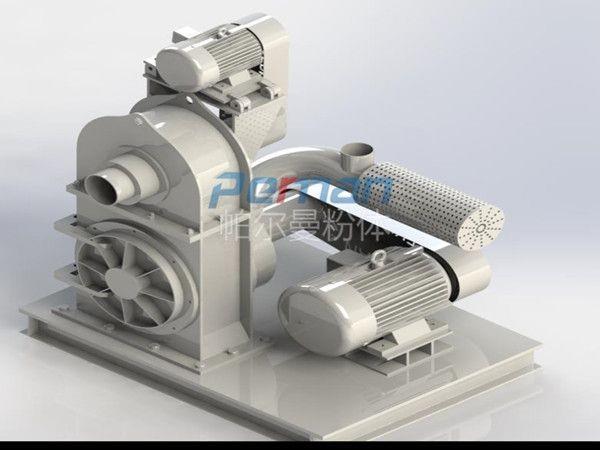

product description

The two-stage impact ultra-micro grinder includes a first-stage grinder. The upper part of the grinder is equipped with a grinding channel, and the upper part of the grinding channel is equipped with a classifier, which is connected by a flange. The classifier is equipped with a fan for sucking the ground material into the classifier. , The lower part of the classifier is provided with a classification channel communicating with the grinding channel. For the secondary grinder, a liner is added at the lower part, a crushing disc is added inside, and an independent door can be set up on one side for easy inspection. Place the secondary grinder under the classifier, the material after the first level grinding enters the secondary grinder along with the airflow and is impacted by the secondary grinding hammer, and the material after the two impacts enters the classifier for sorting, and the fineness is qualified. The material passing through the classification wheel enters the collection system, and the unqualified materials return to the secondary grinding zone for re-grinding. In order to prevent the temperature of the cavity from rising after the secondary grinding, water circulation can be increased on the outer wall of the cavity without damaging the properties of the material. After adding the secondary grinder, for different materials, the capacity and fineness are increased by 30-60% compared with the traditional grinder, thus greatly reducing the energy consumption. Such repetition makes the material crush more finely, and at the same time, there is no problem of material storage, and the utilization rate of the material is improved.

Product advantages

The two-stage impact ultra-micro grinding machine is a new type of ultra-micro grinding machine newly developed by Weifang Perlman Powder Equipment Co., Ltd. on the basis of the traditional grinding machine. The grinding block collides with the ring gear. After grinding, it enters the classification zone with the airflow. Some materials cannot be returned to the grinding zone for secondary grinding, and some materials cannot be returned to the grinding zone due to the limited primary grinding force, so finer particle size cannot be obtained. , And some have to carry out regular slag discharge due to the inability to grind. After the traditional mill smashes and classifies the material, the coarse material can no longer be returned to the grinding system for secondary grinding. Even if it can return to the grinding zone, the grinding force in the grinding zone is weak, so finer particle size requirements cannot be obtained. We can only consider wet grinding or jet mill grinding, which has high energy consumption, extremely low grinding efficiency, and greatly increases production costs. The two-stage impact ultra-micro grinder developed by our company, after adding the second-stage grinder, for different materials, it can increase the capacity and fineness by 30-60% compared with the traditional grinder, thereby greatly reducing the energy consumption. Such repetition makes the material crush more finely, and at the same time, there is no problem of material storage, and the utilization rate of the material is improved.

Related Products

Related cases

Online customization

Quality creates value