Plate chain tube chain conveyor

The plate chain tube chain conveyor is a continuous conveying equipment for conveying powder, small granules and small blocks and other bulk materials. It can be combined horizontally, inclinedly and vertically. In the closed pipeline, the chain piece is used as the transmission member to drive the animal material to move along the pipeline. When conveying horizontally, the material particles are pushed by the chain in the direction of movement. When the internal friction between the material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable material flow; when conveying vertically, the material particles in the pipe are pushed upward by the chain because the lower part The feed prevents the upper material from sliding down and generates lateral pressure, so the internal friction of the material is enhanced. When the internal friction between the material is greater than the external friction between the material and the inner wall of the pipe and the material's own weight, the material will be transported upward with the chain. Form a continuous stream.

In the process of conveying materials, the plate chain pipe chain conveyor has the characteristics of large scraper conveyor conveying capacity, long service life, low maintenance cost, good sealing, safety, and low energy consumption. It also has the vertical conveying of bucket elevator At the same time, the layout is more flexible (horizontal-vertical/tilted-horizontal), and the sealing performance is higher. There is no return material, no damage to the material, and no dust in the vertical conveying of the material. When conveying water-bearing materials, easily adsorbed materials, and materials with very light specific gravity, an electric sweeper can be installed in the case.

In a closed pipeline, the chain is used as a transmission member to drive the animal material along the pipeline. When conveying horizontally, the material particles are pushed by the chain in the direction of movement and move forward with the chain to form a stable material flow; when conveying vertically, the material particles in the tube are continuously pushed upward by the chain to prevent the material from sliding down. , And generate lateral side pressure, which enhances the internal friction of the material. When the internal friction between the material is greater than the external friction between the material and the inner wall of the pipe and the material's own weight, the material moves upward with the chain to form a continuous material flow. The powder material can move linearly or change direction along the closed pipeline in the three-dimensional space; the horizontal conveying distance can reach 60 meters, and the vertical conveying distance can reach 30 meters.

Arrangement form

1. Horizontal type 2. Inclined type 3. Vertical type 4. Three-dimensional layout

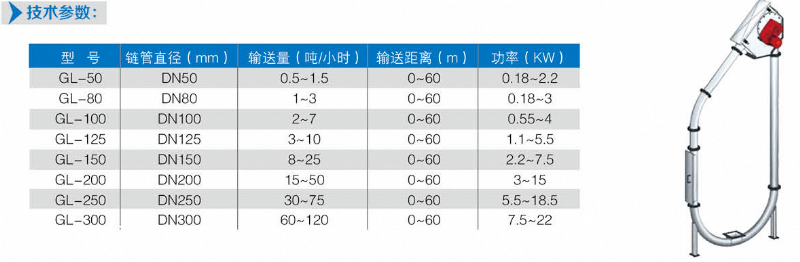

Models and parameters:

The difference between pipe chain conveyor and traditional conveying method:

Pneumatic conveying: 1. High material conveying speed 3-40m/s 2, high abrasion 3, danger of sparking 4, high defective material 5, 20 times energy consumption

Scraper conveying: 1. Dead zone 2. Large friction noise 3, Large abrasion 4. Only horizontal arrangement 5. Large space occupation

Pipe chain conveying: 1. Flexible layout 2. Material conveying speed is 0.1-0.4m/s 3, low wear 4, no sparks 5, keeping product shape 6, lower conveying energy consumption

Layout of pipe chain conveyor:

Related Products

Related cases

Online customization

Quality creates value