Fine Chemical Pipe Chain Conveyor

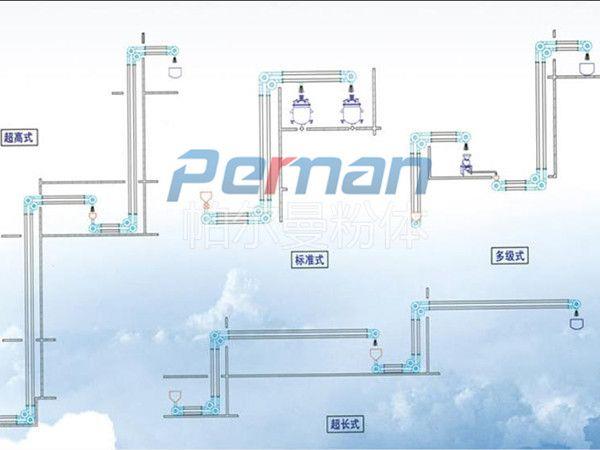

Pipe chain conveyors are also called pipe chain conveyors, pipe conveyors, pipe conveyors, chain pipe conveyors, etc. It is a mechanical system that moves inside a closed tube. It has the characteristics of stable performance, energy saving, environmental protection and sealing in the conveying system. It can continuously convey bulk materials such as powder, paste, small particles and small blocks, and can also be combined horizontally, inclinedly and vertically. It is widely used in various industries such as chemical industry, chemical fiber, pesticide ores, plastics, rubber, grain, pulverized coal, food industry, building materials and so on.

The pipe chain conveyor is a continuous conveying equipment for conveying powder, small granular and small lumps and other bulk materials, which can be combined horizontally, inclinedly and vertically. In the closed pipeline, the chain piece is used as the transmission member to drive the animal material to move along the pipeline. When conveying horizontally, the material particles are pushed by the chain in the direction of movement. When the internal friction between the material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable material flow; when conveying vertically, the material particles in the pipe are pushed upward by the chain because the lower part The feed prevents the upper material from sliding down and generates lateral pressure, so the internal friction of the material is enhanced. When the internal friction between the material is greater than the external friction between the material and the inner wall of the pipe and the material's own weight, the material will be transported upward with the chain. Form a continuous stream. The powder material can move linearly or change direction along the closed pipeline in the three-dimensional space; the horizontal conveying distance can reach 60 meters, and the vertical conveying distance can reach 30 meters.

In the process of conveying materials, the pipe chain conveyor has the characteristics of large conveying capacity, long service life, low maintenance cost, good sealing, safety, and low energy consumption. It also has the characteristics of vertical conveying by bucket elevator Capability, while the layout is more flexible (horizontal-vertical/tilted-horizontal), and the sealing performance is higher. There is no return material, no damage to the material, and no dust in the vertical conveying of the material. When conveying water-bearing materials, easily adsorbed materials, and materials with very light specific gravity, an electric sweeper can be installed in the case.

Features:

1. Compact structure, small space occupation, and the conveying direction can be changed three-dimensionally.

2. Fully enclosed conveying, no dust spillage, no need to set up a dust collector at the outlet. It can be filled with gas when conveying materials.

3. The material is transported smoothly along the pipe, and the material is less damaged, and the slow curved transportation causes a few material particles to produce debris.

4. Low energy consumption-economical operating cost, the whole system is driven by only one motor.

5. No system blockage-suitable for conveying various forms of materials.

Application areas:

Fine chemicals: pigments, dyes, coatings, carbon black, titanium dioxide, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieves, kaolin, silica gel powder, activated carbon, etc.

Pesticide ore: urea, ammonium chloride, ammonium bicarbonate, soda ash, solid pesticides, tungsten powder, pesticide additives, copper concentrate powder, coal powder, phosphate rock powder, alumina powder, etc.

Building materials: cement, clay, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, sawdust powder, glass fiber, silicon dioxide, talc, etc.

Food industry: flour, starch, grain, milk powder, food additives, etc.

Advantages of pipe chain feeding system:

◆The volumetric conveying device can realize the conveying and metering of materials. It is easy to realize centralized control, improve the degree of automation, and meet the requirements of modern enterprises for environmental protection

◆Compact structure, small space occupation, and the conveying direction can be changed three-dimensionally.

◆The material being conveyed is in a closed state from the inlet to the outlet flange. The outlet does not need to be equipped with a dust collector. It can be filled with gas when conveying materials. During transportation, it can be ensured that no dust leaks into the environment.

◆The material is transported smoothly along the pipe, basically without internal movement, so the material is less damaged, and the slow curve transportation makes a few material particles produce debris.

◆According to different feeding conditions, the distance between the inlets can be more than 10 meters.

◆The sprocket has optimized shoulders, optimized design, and the use of hardened chains has less wear.

◆Special conveying plate with very low friction coefficient and stable conveying capacity.

◆All the tube chain conveyors we produce use self-developed calculation programs, so that different parts such as the conveying pipe and bending parts of the conveyor maintain the necessary static friction and tensioning force, and provide high-accuracy data for the design of low noise and low wear .

Related Products

Related cases

Online customization

Quality creates value