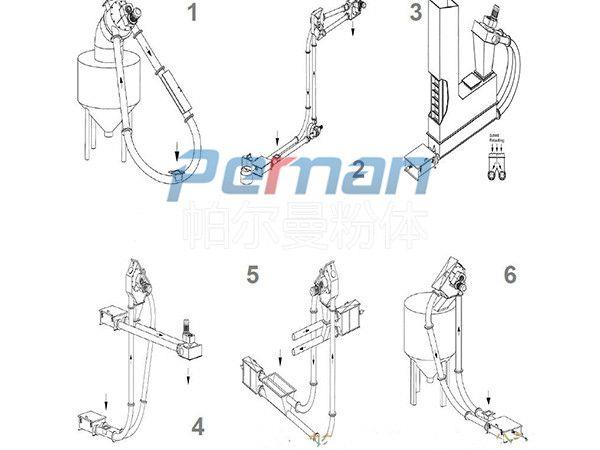

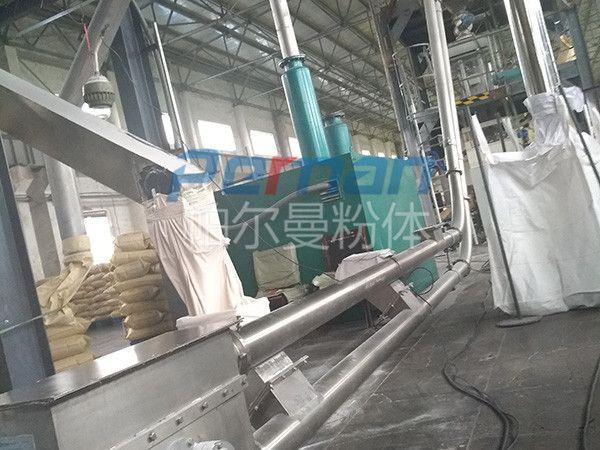

Pipe chain machine

In the closed pipeline, the chain piece is used as the transmission member to drive the animal material to move along the pipeline. When conveying horizontally, the material particles are pushed by the chain in the direction of movement. When the internal friction between the material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable material flow; when conveying vertically, the material particles in the pipe are pushed upward by the chain because the lower part The feed prevents the upper material from sliding down and generates lateral pressure, so the internal friction of the material is enhanced. When the internal friction between the material is greater than the external friction between the material and the inner wall of the pipe and the material's own weight, the material will be transported upward with the chain. Form a continuous stream.

Application field

Fine chemicals: pigments, dyes, coatings, carbon black, titanium dioxide, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieve, kaolin, silica gel powder, activated carbon, etc.

Pesticide ore: urea, ammonium chloride, ammonium bicarbonate, soda ash, solid pesticides, tungsten powder, pesticide additives, copper concentrate powder, coal powder, phosphate rock powder, alumina powder, etc.

Building materials: cement, clay, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, wood powder, glass fiber, silica, talc, etc.

Food industry: flour, starch, cereals, milk powder, food additives, etc.

Performance characteristics:

1. Compact structure, small space occupation, can change the conveying direction three-dimensionally, without being affected by terrain, angle and height; the conveying process is carried out in a closed pipeline, and the material is free of pollution and dust;

2. The conveying process is balanced, there is basically no internal movement between the materials, and there is little damage, ensuring the quality of the materials, suitable for abrasive materials;

3. It will not cause system blockage and is suitable for conveying various forms of materials;

4. The conveying of mixed materials will not produce material stratification;

5. Large conveying capacity, low energy consumption, greatly reducing equipment operating costs;

6. All moving parts run in a confined space, which is safe and reliable;

7. Long-distance transportation can be realized;

8. Multiple inlets and outlets can be deployed at will to meet process requirements;

9. It is easy to realize centralized control and improve the degree of automation.

Related Products

Related cases

Online customization

Quality creates value