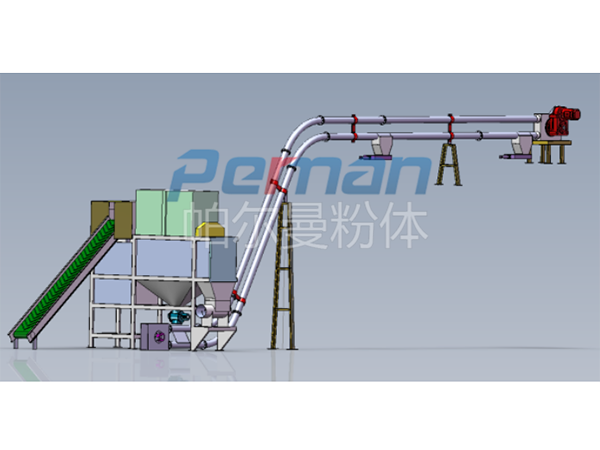

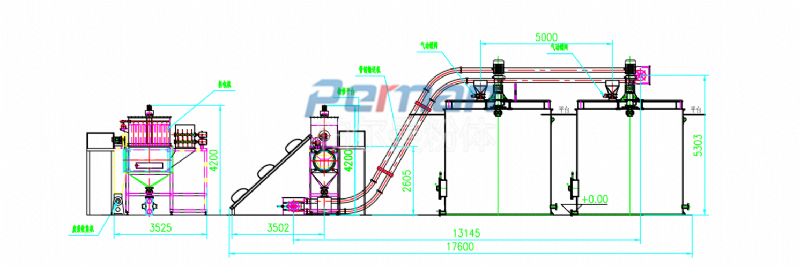

Automatic unpacking machine

Product introduction: The automatic unpacking machine is a dust-free unpacking equipment with automatic production and processing. Our companys unpacking machine is used for unpacking and unloading bagged powder and granular materials. In the fields of

Product introduction:

The automatic unpacking machine is a dust-free unpacking equipment with automatic production and processing. Our company's unpacking machine is used for unpacking and unloading bagged powder and granular materials. In the fields of chemical industry, petroleum, building materials, metallurgy, electric power, food, medicine, grain, environmental protection and other fields, automatic unpacking and unloading of dry powder materials, such as nitrate lime, magnesium oxide, quartz sand, limestone, wood chips, protein powder, Activated carbon, milk powder, PVC powder, fly ash, urea, clay, gypsum, cement, sewage treatment powder, etc. can be automatically unpacked and unloaded. It automatically feeds the bag through the belt conveyor, and the cutter device automatically breaks the bag. , Vibrating screen, automatic bag separation, unloading and other steps, materials fall into the hopper by gravity to complete the bag unloading and unloading work. The dust generated during the operation is filtered by the carried dust removal device, so that the workers can work in a clean environment.

Product composition:

1. Feeding device 2. Bag breaking device 3. Separation device 4. Dust removal device 5. Conveying device 6. Automatic controlBag breaking capacity: 100-800 bags/hour

Machine power: 10-17KW

Note: The configuration, output, material, power, etc. of the whole set of equipment of the automatic unpacking machine are changed due to changes in the nature of materials, use occasions, and discharging methods.

Technical features:

1. During the bag breaking process and the material separation process, the materials are fully enclosed, and each process has a dust collection device, no dust leakage, low noise, and improves the working environment of workers.2. Only one or two people are required to place the packaging bags on the belt conveyor on site, which reduces the work intensity of the workers.

3. The operation of the equipment is simple and reliable, and the failure rate is low, which reduces the maintenance workload.

4. The equipment is specially designed to perfectly separate the broken packaging bag from the material, will not be mixed into the material, and will not hang in the separation device.

5. The equipment automatically counts, and the bagging amount can be set arbitrarily, and the equipment will automatically stop when the bagging amount is reached.

6. When the equipment fails, it will automatically alarm, emergency stop, protect the equipment and avoid personnel misoperation.

7. After bag breaking, unloading and separation, it can be used with other conveying equipment to complete the functions of powder conveying and storage.

8. It can handle different sizes of packaging bags without adjusting the equipment.

Related Products

Related cases

Online customization

Quality creates value